(I) Technical approach section

At the first part, you will find some parameters and tools used specifically by INFOR ERP. Some concepts can be applied in any logistics, and inventory company regardless of the software used.

Distributors perspective of this industry

INFOR ERP Approach

Sections

Main parameters used for INFOR inventory

POs and SOs

POET: create or modify POs.

OEET: create or modify SOs.

OEIO: invoiced orders inquiry.

Purchasing

-POERA: run report to see the system suggested POs. POERR & ICAMM can do similar actions.

-ICAMU: Set multiple items parameters like status or lead time at once.

Standard pack

ICSP: set weight and cubes for each item.

ICSEU: set layers or pallet configuration.

Status of each item:

STK: Stock

OAN: Order as needed

DNR: Do not reorder

Usage

Lead Time

Safety stock

Vendor / MOQ

Product Line

Order Point

Line Point

Weight, cubes and pallets

The first three steps of the implementation are executed only once (except for the usage).

The ICAMU exceptions report and POERA are run every month in order to execute the replenishment of inventory.

Do not try to understand the technical acronyms if you have not used INFOR Software before. The point of following these steps is that there are parameters for each product and based on these specifications, purchase orders are generated through an algorithm in this inventory software.

Be sure that all STK items have a regular demand

Correct usage when convenient and set parameters correctly

Dimensions should be precise

Run report to identify inventory novelties

Run report and order the needed items

With vendors and product items there are easy and difficult scenarios.

In this section are presented some typical circumstances to be faced, as well as some tips.

Let’s before consider, and define what are the most simple or ideal situations.

Vendors

Imagine you have a worldwide popular product, but the vendor changes codes for the same item every three months. You would end it up having six (6) different SKU codes for the same item!. Calculating the demand for this, becomes challenging. No matter if a spreadsheet is used, or an ERP Software. Certainly you must plan a strategy to calculate the minimum quantity in the WH, otherwise you will run out of stock. Changing the vendor is not an option, since consumers highly prefer this particular brand.

For instance, you can ask for “X products” in “Y quantities”, but the provider sent the wrong quantities, plus adds “Z products”. Of course ending the relationship is not a possible scenario because they offer highly demanded products by customers. One way to handle this is by not holding any stock. Only do procurement for the demanded items by customers, and return the ones that mistakenly arrived to the WH.

Some companies are giant and simply do what they want. They force distributors to buy a high yearly quota. They rarely accept a return on merchandise, even if they send you wrong items. The challenge is, that the final consumers have an outstanding demand for their products. Unless you are willing to sacrifice profit, you must run strategies to handle complicated situations with these vendors.

Product Items

Are relatively resistant to weather so they don't require temperature regulation in the WH or the transportation.

Think about milk and other fresh beverages. They are sensitive to weather and can get damaged if not treated properly in the warehouse or transportation. It is not recommended to hold any stock for long unless you are the manufacturer. If a distributor handles a minimum stock and miscalculates the demand, much product will be lost. This could jeopardize the profit of the company. It is better to do procurement pulled from the customers demand.

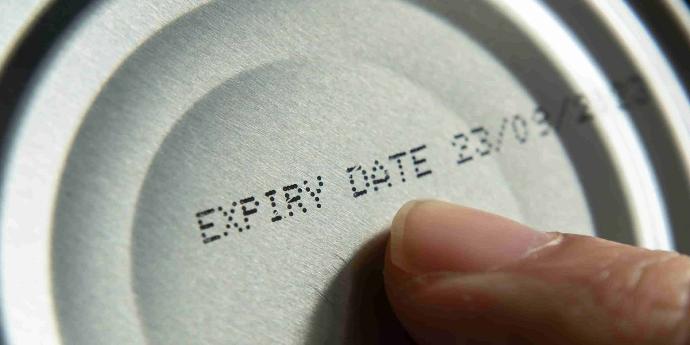

Having a minimum or even safety stock can be decided by the operations manager. In that case, a sales strategy should be coordinated with the sales manager to get rid of the close to expire products. Special promotions can work or even donations to NGOs. Anything necessary to protect the the company's finances. Just consider when a product expires: that inventory automatically becomes a financial loss in the income statement.

Law regulates some imported items which might require special certificates, fees, taxes, and are sensitive to penalties.

Let’s say you have “A to Z customers”, but “Z customer” from a particular region, has an irregular demand, which is actually too high. While typical customers order tenths of cases, this one orders thousands.

Calculating a minimum quantity is risky since you might overstock your WH. To avoid this, it could be convenient to hijack the item, and duplicate it in your ERP software. There would exist the item 0001A for regular customers, and a copy 0001Z that would be used in the system only for “Z customer”.

That means that for normal clients, you can keep calculating a minimum order for item 0001A, but when “Z customer” makes an order , you will use item 0001Z without a distortion in the average demand for the rest of the customers.

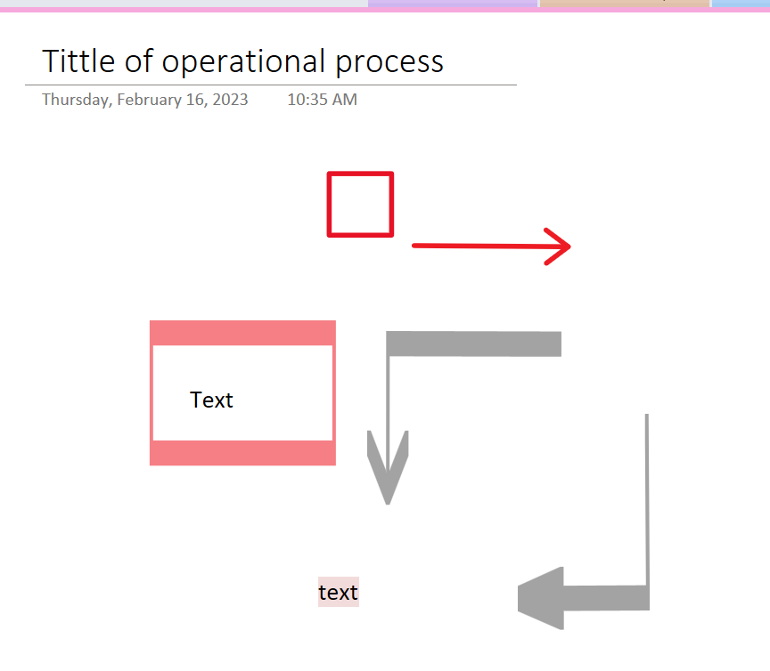

Documentation

SHARE AN OPERATIONS MANUAL!

This is better known as a standard operating procedure (SOP).

An SOP provides detailed instructions on how different tasks combine to execute operations.

No matter if you own the user friendly Odoo or a complex tool like INFOR.

Procurement and inventory staff, should have a guide of the ERP software used in the company.

That is especially useful for new employees.

Operations could be explained with diagrams in Bizagi, MURAL or Microsoft Onenote.

It is key to reduce mistakes, optimize knowledge, and have an efficient employee training.